Lotus Esprit Manufacture

Photo's taken of the Lotus Esprit production line at the Lotus Factory at Hethel (pictures taken 1988).

Click on images to enlarge

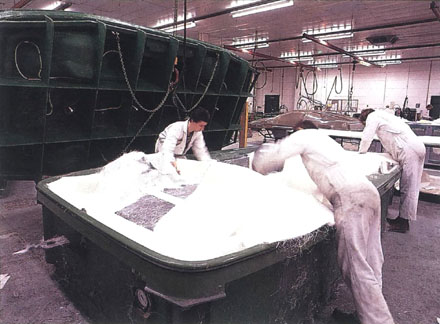

Rolls of glass fibre mat is where it all begins. The mat is cut into shapes along it's grain, using templates and stored ready for use.

Here, the female mold for an Esprit shell's top half is being polished with a release agent, so that the gel coat will not stick when it is released from the mold.

Then the pre-cut glass fibre pieces are laid into the mold. Glass fibre rope, or roving, is used to tie together sections which meet at awkward angles.

The male mold is also sprayed with release agent and put into position. Resin injection is the next step, the rubber seal, visible round the mould's edge helps maintain the vacuum.

An hour after it was injected, the resin has cured and the mould is popped with compressed air to release it from the newly formed body. then off comes the male moulds half, to reveal a brand new top body section inside. It is still warm from the exothermic resin curing process, but ready to come out.

The shell is removed from the mould, still warm. The shell is shiny on the outside, but its glass fibre texture shows on the inside. Its resin thinkness is closely controlled throughout, thanks to the precesion of the VARI process.

The top and bottom halves are clapped and glued together, the excess epoxy resin is squeezed out by the clamping pressure.

The translucent body shell looks much less like an amorphous bob once the holes and apertures are cut out. Amoung the first to be cut are the wheel arches. The GRP is cut with an air-powered cutter.

Between spraying the many coats of paint, the body is rubbed down and washed to ensure the smoothest finish possible.

Mean while the upholstery is being made for the interior. Here the leather is being cut for the dash board binnacle.

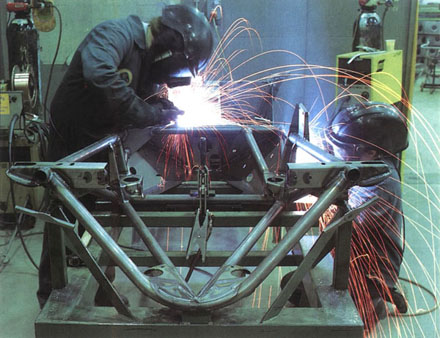

The chassis, which is fabricated in sheet steel with a tubular engine cradle, is welded together on a jig to ensure accuracy. Once complete, it is sent away to be galvanised.

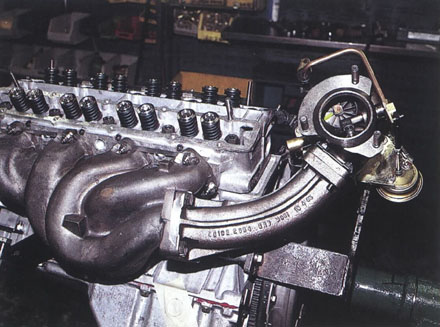

Here the engine is assembled. Above work is being carried out to the oil pump.

An Esprit Turbo engine near completion.

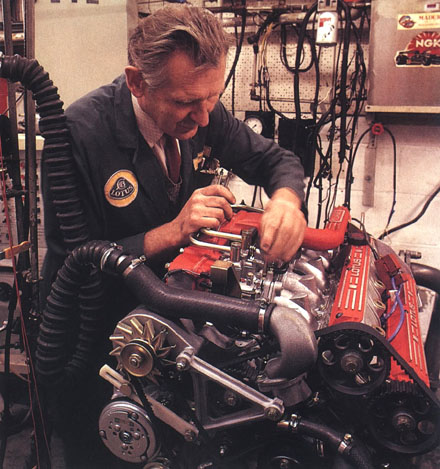

Newly built engines are run the in test cell for half and hour, building up speed in gentle stages. The the carburettor and ignition settings are carefully adjusted and faults can be put right.

Finally the finished engine is mounted to the chassis.

The finally ancillaries are fitted the the chassis before the body shell is fitted.

The body shell is lowered to the chassis and fitted. The winch cables are hooked into moulded protection plates to prevent body damage.

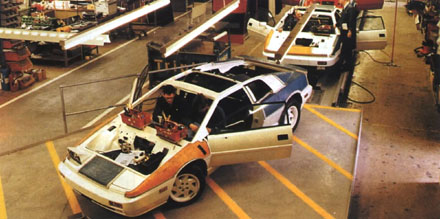

The asssembly line; the interior seats, dashboard and doors are fitted.

The final part of the assmebly line.

Finished Lotus Esprit's park along side the final stage of the assembly line.

Click on images to enlarge